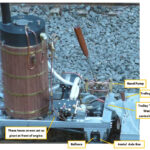

In January 2022 Maurice wrote about his compact steam plant & included the line ‘May be able to power a 5″ driving trolley at up to 5mph’.

Well, he has built the driving trolley & it does! Here is Maurice’s story:

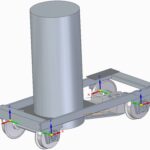

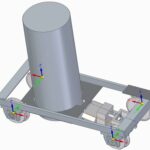

‘The underlying idea was to end up with a compact lightweight 5” gauge “locomotive” where the driver provided most of the adhesive weight.

The existing plant hopefully included suitable reduction gearing.

Design Issues included:

- Designing a chassis dimensioned to accommodate the engine and boiler.

- How to drive the wheels

Ideas for driving the wheels included:

Plan A – Simply putting the wheels on the existing shaft

Plan B – Chain drive (already have a suitable chain and sprockets).

The design issues highlighted the fact that I’m not a trained draftsman. MS Word was used to date, mostly for small parts like boiler fittings. Definitely not 3-D and hard work for e.g. adding dimensions.

Ended up using Solid Edge 3-D design software. Chose Solid Edge because the Community Version is free and provides comprehensive facilities. Limitation is apparently that you can’t open the resulting design files with the Commercial Version.

Reasonable tutorials can be found on YouTube with a little trial and error (Some only have a commentary in Hindi/Urdu!).

End result was I now use Solid Edge for designing even simple parts – I especially like the comparative ease of producing dimensioned 2-D drawings from the 3-D design.

Design showed that Plan A above would work if the driving wheels were large enough.

Note that the engine pivots up and down with the axle (c.f. a motor scooter).

Used aluminium angle and bar for the chassis to keep the weight down. Considerations when using aluminium include:

- It’s apparently comparatively OK in contact with stainless steel.

- It shouldn’t be in contact with copper and brass (ferocious electrolytic corrosion especially in a warm damp steamy environment!)

The driving wheels are 65mm diameter and the reduction gearing is 2.5:1. Thus at 5 mph the engine would be running at 1642 rpm.

Comments about the resulting loco:

- It looks like nothing on earth, and it could be difficult to make it look like a real tram loco

- It’s easy to drive and fire compared to my 3.5” gauge Petrolea Tank.

- It’s much lighter than my Petrolea Tank, so I can bring it to the site without needing a taxi.

- It can reach an alarming speed and run up the banks with little loss of speed. see #1 below

- The engine is slow to warm up and it takes a bit of pushing up and down with the drain cocks open to get the water out of the cylinders.

- The slip eccentric means that you need be sure you’re not in reverse before starting. I hope to make a more positive arrangement in due course. (e.g. the eccentric moved from forward to reverse by a hydraulic piston)

Teething Troubles and Modifications

- The key locking the driven gear to the axle fell out. Luckily I found the key and jammed it in with a twig as a temporary fix. I’ve now made a new key with a tighter fit and held it with a screw to stop the key sliding out along the keyway.

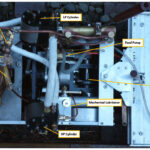

- The displacement lubricator emptied far too quickly (apparently they’re notorious for dong this). It then lost its drain screw (if you find a small knurled brass screw on the 3.5” track then it’s mine!). I’ve now fitted a mechanical lubricator instead. This works well, but resulted in an oily mess dripping from the funnel! It’s now been fitted with a longer lever to reduce the feed rate.

- Even with the damper closed the safety valve constantly lifts even when the engine is working hard. I’ve now blocked some of the air-holes in the ashpan to try and address this. I can always open the damper if there isn’t enough steam.

- The water gauge blowdown drips constantly. (very irritating). Will replace the plug cock with a screw-down valve.

I guess it would be able to cope with higher gearing, but I’m happy with it at the moment. It may feel like it’s going fast, but it may well only be doing 5 mph. I intend to get an electronic rev. counter to work out the actual speed as basic ones are certainly cheap enough.