The Bathgate Locomotive works have been on bit of an intentional go slow this past week. Robert brings us up to speed:

“The awaited rolled smokebox wrapper arrived. It is 2.5mm thick steel & I need to make a jig in order to bend the two ends to a vertical fit between the frames.

“The awaited rolled smokebox wrapper arrived. It is 2.5mm thick steel & I need to make a jig in order to bend the two ends to a vertical fit between the frames.

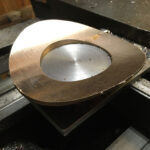

Trying the chimney base prior to machining it to match the smokebox curve. Bit of a saga with the delivery of the wrapper, the supplier had to put the item into quarantine after it was returned from being rolled. This delayed the dispatch onwards to me. Most frustrating…….

Trying the chimney base prior to machining it to match the smokebox curve. Bit of a saga with the delivery of the wrapper, the supplier had to put the item into quarantine after it was returned from being rolled. This delayed the dispatch onwards to me. Most frustrating…….

The turning of the base was done by hand which was a tad time consuming. You may ask why I didn’t use power.

The turning of the base was done by hand which was a tad time consuming. You may ask why I didn’t use power.

The answer is in the way I set up the lathe tool:

I didn’t to risk the tool flying out of the chuck & damaging the job (or me!).

I didn’t to risk the tool flying out of the chuck & damaging the job (or me!).

It worked well, very theraputic.

Here is the completed job, a perfect fit.

Here is the completed job, a perfect fit.

The flange is still to big & a lot of hand filing is required for the next stage. Roll on the next wet day!