Chris kindly invited the News Desk to view the progress to date on his magnificent 2-6-2. To say that the News Desk was left speechless by what he saw is an understatement!

Here are some photographs accompanied by the words that he can remember!

After Chris & Hazel had brewed a cup of Rosy Lee & passed a mug over we went into Chris’s workshop which is in one of the front rooms of the house. Opening the door revealed not only the tidiest workshop I have ever seen, but the most magnificent green beast virtually filling the room!

The backhead is a scale representation of the real locomotive. The regulator linkage is more complex than found on a UK locomotive & just look at the firehole door with those rollers! The two devices that look like safety valves on either side of the backhead are in fact lifting injectors. However, Chris was unsure about getting them to work in this scale thus they are not fully functioning, but they do supply the steam to ‘normal’ injectors below the footplate. All valves are hand made to the originals. The attention to detail is astounding.

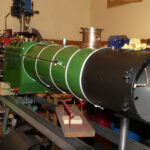

The boiler is a big beast! This and the driving wheels are the only items Chris purchased, although the boiler is to his own design. The superheaters are radiant & there are brackets provided in the smokebox to hold the headers at the correct height to ensure a proper flow of heat for best efficiency. The dome has been removed as when under a test Chris was unhappy about the regulator sealing correctly. Rather than leave this to chance that it would ‘be alright on the night’ he has chosen to strip it down to cure it.

The boiler is a big beast! This and the driving wheels are the only items Chris purchased, although the boiler is to his own design. The superheaters are radiant & there are brackets provided in the smokebox to hold the headers at the correct height to ensure a proper flow of heat for best efficiency. The dome has been removed as when under a test Chris was unhappy about the regulator sealing correctly. Rather than leave this to chance that it would ‘be alright on the night’ he has chosen to strip it down to cure it.

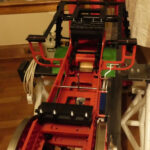

At the front end, Chris sourced Pea Bulbs for the headlights. He tried LED’s but they didn’t look right. The knuckle coupler is American sourced. Oh, and when the original was built the railway was moving from screw coupling which required buffers, to knuckles that didn’t. During the transition the locomotive ran with both a knuckle & buffers. Note the tail rod. The cylinders are 3″ diameter, so she will be a powerful beast.

Looking along the frames, in the left picture you can see the saddle for the smokebox. Being a design from the former Soviet Union there was no issue with loading gauge restrictions, it’s 17 feet! As a result the boiler is pitched much higher than one would expect in either the UK or the rest of Europe. The loco is air braked at 15 psi, the reservoir can be seen in the middle of the frames. The right hand photo shows the footplate end & where the firebox will sit. This will have a drop grate which in turn falls into a hopper type ash pan. It is not possible to remove the ash pan.

A close up view of the motion work shows the crispness of machining. The bottom of the motion brackets are joined across the locomotive. This would prevent the connecting rod dropping onto the track in the event of a failure of the little end. If this occurred then the locomotive would be thrown over as has occurred in this country. The tender is enormous! One feature that took my attention are the tri-cocks on the rear of the body. These are for testing the water level in the event of the tank lids being frozen shut in -35 degree frost! Not sure how that would help as the next question would be how do you fill it if it’s low on water?

The paint finish is from Spray Can Cellulose, which given the area to be sprayed using a can the finish is perfect.

I hope this gives you a flavour for what is going to be one incredible locomotive when it gets out on the track. I can’t wait to see it.